Well here is how it started out:

I am starting with a 48*24*28 reef ready tank. Converting the dual overflows into a coast to coast bean animal. Going to be a black background, black stand and canopy, and re do the door so it opens like a regular door instead of lifting up.

C2c test fitted and siliconed in as well as back glass painted black.Also notched out part of the dual overflows so the coast to coast will actually function.

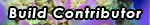

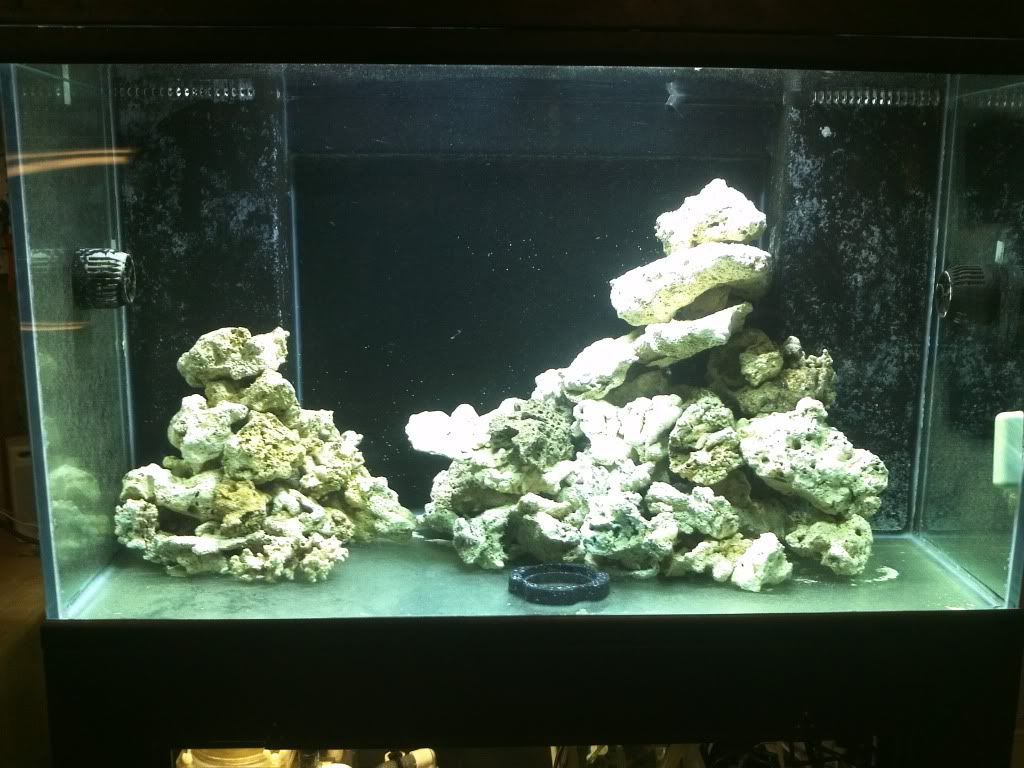

Side view

Doors are cut, now to hang them and paint them.

And the inside painted:

Plumbing Done, front left, emergency and syphon

Front right return and wet:

Plumbing underneath done brs reactor installed:

Apex temporarily installed(stopped working because I messed up the firmware update, but later fixed and reinstalled it)

And here it is reinstalled:

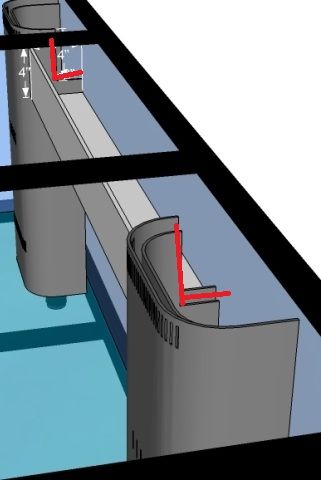

1st batch of rockwork and waiting to fill it with RODI:

And filled with RODI

Skimmer in place along with fan wired up:

Vortech controllers mounted underneath the top of the stand, Velcro and zip tied:

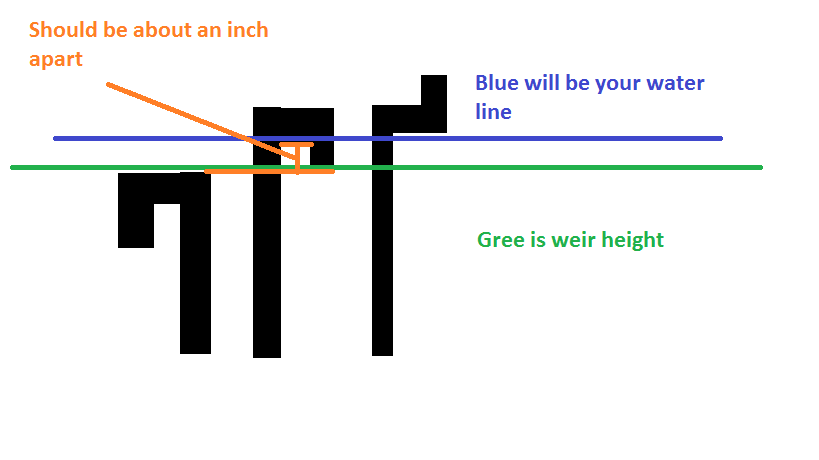

Although not in order this is how the plumbing is set up between the two overflows:

With new rock in the tank, still need help with aquascaping:

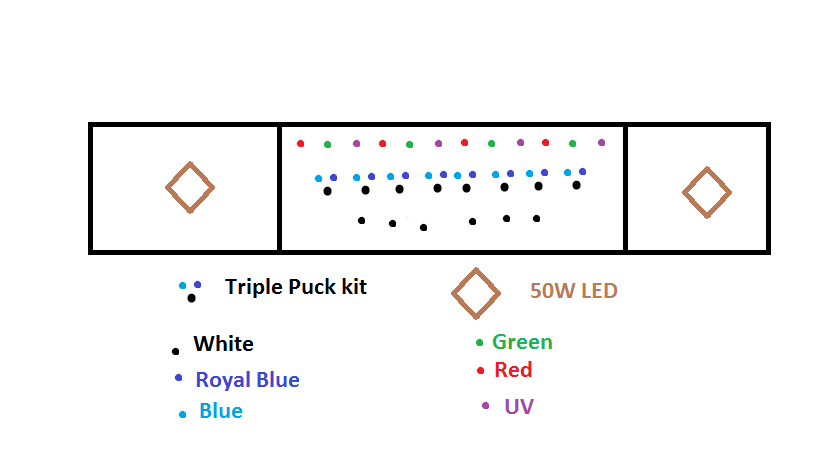

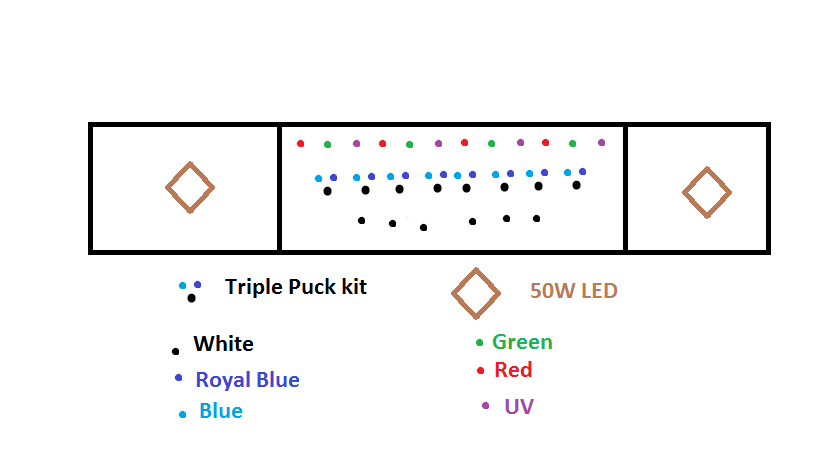

Proposed LED set up mock up:

Equipment list:

Apex(full) with 2 EB8s, break out box, WXM,Custom sump, DIY LED Lights, Apex, MP40, MP10, 2-6025's, Schuran Jetskim 150w/ Eheim 1260, ecoplus1056 for the return pump, ATO handled by apex with an aqualifter.

Intended list:

VDM to control the 50Wleds, 2 BRS dosing pumps(or BMT01), 2-50w LEDs and drivers

Possible over time:

Another mp40 or mp10 or put 2 tunze 6095s in the back.

Avast swabbie with skimmate locker

So officially the agreement with my wife is since I got to upgrade(coming from a 75) I dont get to set it up until we leave in May. SOOOO,I am curing my rocks, pulling every last piece of nutrients off of them(and there is a lot) making sure everything functions as it should until then, then when I set it up, remove the plumbing a few parts of electrical and the thing should go back together fairly simple. Thats the plan At least I get to look at a tank while I am waiting this way.

So this build is going to take a while, I only spend about 15min a day(after I get ready before I leave for work) on it, and there is only so much you can do. The plan when I set it up is going to be a mostly softie tank with LPS and although its TBD, a few tangs in the tank.

I am starting with a 48*24*28 reef ready tank. Converting the dual overflows into a coast to coast bean animal. Going to be a black background, black stand and canopy, and re do the door so it opens like a regular door instead of lifting up.

C2c test fitted and siliconed in as well as back glass painted black.Also notched out part of the dual overflows so the coast to coast will actually function.

Side view

Doors are cut, now to hang them and paint them.

And the inside painted:

Plumbing Done, front left, emergency and syphon

Front right return and wet:

Plumbing underneath done brs reactor installed:

Apex temporarily installed(stopped working because I messed up the firmware update, but later fixed and reinstalled it)

And here it is reinstalled:

1st batch of rockwork and waiting to fill it with RODI:

And filled with RODI

Skimmer in place along with fan wired up:

Vortech controllers mounted underneath the top of the stand, Velcro and zip tied:

Although not in order this is how the plumbing is set up between the two overflows:

With new rock in the tank, still need help with aquascaping:

Proposed LED set up mock up:

Equipment list:

Apex(full) with 2 EB8s, break out box, WXM,Custom sump, DIY LED Lights, Apex, MP40, MP10, 2-6025's, Schuran Jetskim 150w/ Eheim 1260, ecoplus1056 for the return pump, ATO handled by apex with an aqualifter.

Intended list:

VDM to control the 50Wleds, 2 BRS dosing pumps(or BMT01), 2-50w LEDs and drivers

Possible over time:

Another mp40 or mp10 or put 2 tunze 6095s in the back.

Avast swabbie with skimmate locker

So officially the agreement with my wife is since I got to upgrade(coming from a 75) I dont get to set it up until we leave in May. SOOOO,I am curing my rocks, pulling every last piece of nutrients off of them(and there is a lot) making sure everything functions as it should until then, then when I set it up, remove the plumbing a few parts of electrical and the thing should go back together fairly simple. Thats the plan At least I get to look at a tank while I am waiting this way.

So this build is going to take a while, I only spend about 15min a day(after I get ready before I leave for work) on it, and there is only so much you can do. The plan when I set it up is going to be a mostly softie tank with LPS and although its TBD, a few tangs in the tank.